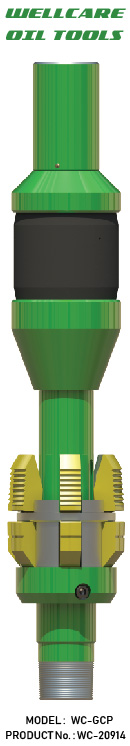

COMPRESSION SET RETRIEVABLE PACKER

- WC-GCP / WC-20914

The WELLCARE Model WC-GCP Retrievable Casing Packer is a compact, economical set-down packer that can be used by itself for production applications or, with a companion un loader and hold-down, it can be used for well stimulation, testing and other pressuring operations and then left in the well as a production packer.

FEATURES & BENEFITS

- Short And Compact – Even shorter and more compact than its predecessor, the Model “GCP” Retrievable Casing Packer offers true ease of storage, shipping and handling.

- Permits Passage Of Recording Instruments – The bore through the Model WC-GCP Packer is full- opening for the size tubing on which it is designed to be run. Pressure bombs or temperature recording devices can be run through and below the tool if desired.

- Low Cost – Economical to buy and economical to maintain, the Model WC-GCP Retrievable Casing Packer offers long and dependable service with minimum care and maintenance.

- Alternate Packing Element System For temperatures up to 250° F, the standard 80 hard packing elements can be used with the Model WC-GCP Packer; for applications above this temperature, the packer is furnished with a 90 hard packing element.

- Simple Construction – As is evident in the drawing on Page 2, the Model WC-GCP Packer is constructed of a minimum number of working parts. The dependable rocker-type slips and synthetic rubber packing element are the same types used on other highly successful Baker equipment.

- Ease of Operation – A simple and reliable J- Slot mechanism, actuated from the surface, makes the Model WC-GCP Retrievable Casing Packer very easy to set and release.

- Alternative Body with Larger ID – An Alternate Body is available, with an ID of 1.978″, in Size 43 only. The Alternate Body is used in areas where a pump is to be run below the packer or where it is desired to swab below the tool.

OPERATIONAL BENEFIT

- Furnished with different feed through options compatible with tubing encapsulated cable line, control line

- No mandrel movement for setting.

Available Size

4-1/2 INCH

0

mm

To

13-3/8 INCH

0

mm

* For Specification guide please refer Specification Sheet supply with each Product.